Today’s domestic all-wheel drive (AWD) systems are designed to operate in conjunction with many of today’s vehicles’ on-board systems, such as the engine performance system; transmission control system; antilock brake system, which may also include the vehicle ride and stability control systems; and other systems throughout the vehicle.

In this article, we’ll look at the different types of domestic AWD systems available today and provide you with a basic understanding of how each of these domestic AWD systems operates.

DOMESTIC AWD SYSTEM CATEGORIES

Generally, there are two categories of AWD systems available on today’s domestic cars, vans, and crossover vehicles. These systems are referred to as:

- On-demand AWD systems

- Fulltime AWD systems

ON-DEMAND AWD SYSTEMS

On-demand AWD systems, unlike fulltime AWD systems, only operate when the demand or circumstances require AWD operation.

The on-demand system can use a mechanical device, such as a gerotor system, like GM’s Versatrak system, found in Montana’s, Silhouettes, Aztecs and Rendezvous. Or they can use an electronic coupler system, found in Saturn’s AWD system, Ford’s intelligent AWD system, and Chrysler’s interactive torque management system.

FULLTIME AWD SYSTEMS

These fulltime AWD systems appear in GM vehicles, such as the Chevrolet Express or GMC Savana vans, GMC Yukon, and Cadillac Escalades.

Chrysler uses a similar fulltime AWD system in their Jeep lineup. The Pontiac Vibe uses a viscous coupler system, known as the synchronous viscous coupler system, to achieve AWD.

COMMON COMPONENTS

The on-demand and fulltime AWD systems have a several components in common. These components include a:

- Transfer case or power takeoff unit (PTU)

- Driveshaft to distribute torque to the front or rear differentials

- Front or rear differential (or both, depending on application)

Now let’s look at these AWD systems, so you can get a better understanding of how each system operates.

DOMESTIC AWD SYSTEM TYPES

There are four types of AWD systems available in the domestic automotive market today. They are:

- Versatrak AWD System

- Electronically Controlled Coupler AWD System

- Fulltime AWD System

- Synchronous Viscous Coupler AWD System

Now let’s take a closer look at each of these systems.

VERSATRAK AWD SYSTEM

The Versatrak AWD system is a one-speed, AWD system found on GM‘s Montana, Silhouette, Aztec, and Rendezvous. While it’s a hydromechanical system, it uses electronics for system protection.

The PCM doesn’t engage the AWD system; it only controls the clutch pump check valve during abusive situations to prevent damage, or it’ll kick in while you’re driving on a spare tire. The system is often referred to as the Steyr system.

The Versatrak system consists of three major components:

- Transfer case assembly

- Propeller shaft/driveline assembly

- Rear differential assembly

The design of this component changes power output from transverse to longitudinal and positions the propeller shaft assembly near the centerline of the vehicle.

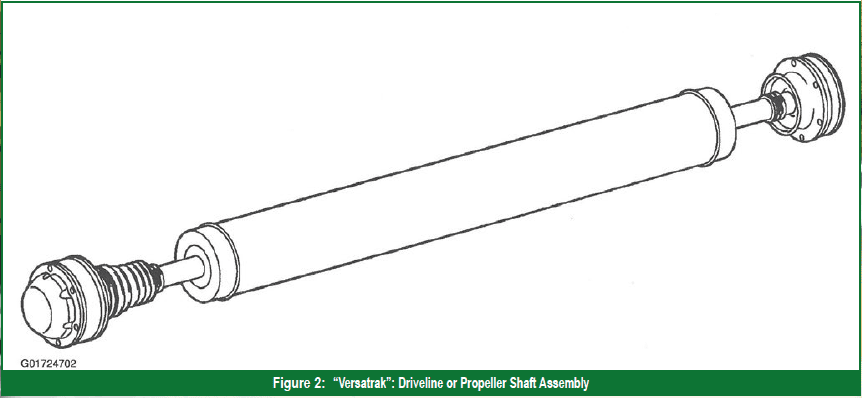

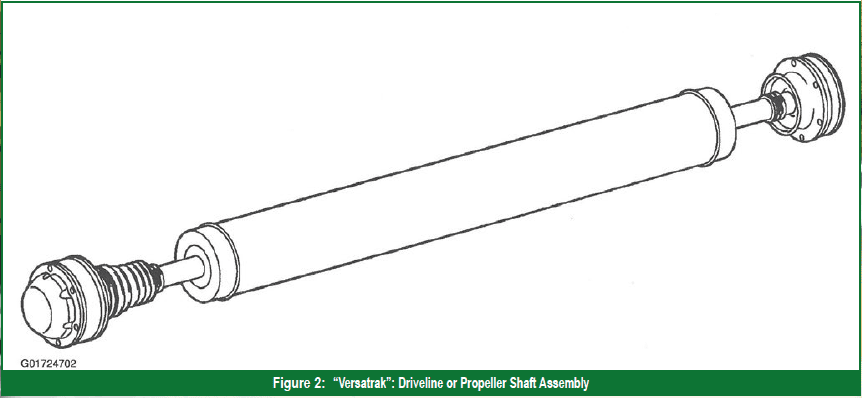

Propeller Shaft/Driveline Assembly — The propeller shaft assembly consists of a one-piece aluminum tube with front and rear constant velocity joints (figure 2). The rear constant velocity joint is a plunging design and will move forward and rearward as needed.

The propeller shaft assembly connects to the output flange of the transfer case and the rear differential input flange by retaining bolts.

The aluminum torque tube housing contains an internal drive shaft that’s supported by roller bearings at each end of the tube.

The internal driveshaft is attached to the front propeller shaft assembly by bolts, and is splined to the differential pinion shaft.

The pinion shaft is positioned in an aluminum pinion housing and is supported by tapered bearings. A shim between the pinion and differential housing provides the proper backlash for the ring and pinion gears.

The ring gear bolts externally to the differential carrier assembly.

The rear differential assembly uses the same type of synthetic gear oil that hypoid gears use. The rear differential carrier assembly consists of left and right side clutch pack drums, separate left and right axle subshafts, left and right gerotor pump components, left and right clutch packs, left and right pistons, and the internal valves.

VERSATRAK SYSTEM OPERATION

The propeller shaft, or driveline assembly, is constantly rotating and spins about the same speed as the front wheels. Under normal, straight-ahead, non-slip driving conditions, the external and internal gears of the differential gerotor pumps are rotating at an equal speed. Under those conditions, the pumps create no pressure, no clutch packs activate, and no torque transfer occurs.

If a front wheel begins to slip, the external gears of the gerotor pumps rotate at a faster rate than the rear-wheel-driven internal gears. The gerotor pumps pull oil from the sump through the clutch pump check valve, sending pressurized oil to each individual piston to activate the separate clutch packs. The system then provides torque to each of the rear wheels as required.

A valve internal to each piston housing controls maximum clutch-pack pressure. Secondary valves, located in each of the housings, are temperature compensating and control fluid flow based on ambient temperature.

The system operates in both forward and reverse. Now that you have a better understanding of how the Versatrak AWD system operates, let’s look at the electronically controlled coupler and the systems that control it.

ELECTRONICALLY CONTROLLED COUPLER AWD SYSTEM

The electronically controlled coupler AWD system has been incorporated into most of today’s domestic automakers’ lineups. These AWD systems are always active and are referred to as intelligent AWD systems.

These systems combine transparent, all-surface operation and are capable of handling just about any road condition, including street and highway driving, and off-road and winter driving. Depending on the manufacturer, some of these intelligent AWD systems allow the driver to select specific AWD modes of operation.

During normal operation, the system sends most of the torque from the transmission to the front wheels. If the system detects slip between the front and rear wheels, or if you’re operating the vehicle under heavy throttle conditions, the intelligent AWD system will increase the torque to the rear wheels to prevent or control wheel slip.

The intelligent AWD system consists of a transfer case or power takeoff unit (depending on vehicle application); a rear driveshaft; an electronic, on-demand coupler device; a rear axle; a coupler device control module, known as the 4WD control module (4WDCM); and a differential electronic module (DEM) or an intelligent torque control coupler module (ITCC), depending on the application.

ELECTRONICALLY CONTROLLED COUPLER

The electronically controlled coupler is attached to the rear differential (figure 4). The purpose of the electronically controlled coupler is to transmit torque to the rear wheels by way of a two-stage clutch system.

Now let’s look at what controls the electronically controlled coupler all-wheel drive control system.

CONTROLLING THE ELECTRONICALLY CONTROLLED COUPLER AWD SYSTEM

The electronically controlled coupler AWD system is controlled by any of these modules, depending on application:

- AWD control module, also known as the 4WD control module (4WDCM)

- Intelligent torque control coupler module (ITCCM)

- Differential electronic module (DEM)

- Drivetrain control module (DTCM)

The AWD control module uses inputs from various on-board systems to control the all-wheel drive system operation (figure 5). These include the:

- Powertrain Control Module (PCM)

- Antilock Brake System (ABS)

- Traction Control System (TCS)

- Vehicle Stability (VSC) Module

Problems in any of the on-board computer or communication systems will interfere with the electronically controlled coupler AWD system, so you’ll want to correct those problems before attempting to diagnose any problems with the AWD system.

Now that we’ve looked at the on-demand AWD systems, let’s look at the fulltime AWD systems available from domestic automakers.

FULLTIME AWD SYSTEMS

The viscous coupler is capable of absorbing the difference in speeds between the front and rear wheels.

Now let’s look at our final fulltime AWD system: the synchronous viscous coupler system.

SYNCHRONOUS VISCOUS COUPLER SYSTEM

The Pontiac Vibe uses a unique, one-speed, fulltime AWD transfer case or power takeoff unit (PTU), a driveline assembly, and a viscous coupling at the rear axle (figure 7), to provide torque to the rear axle when the front wheels lose traction. The viscous coupler isn’t serviceable; you’ll have to replace it as an assembly.

These fulltime AWD systems are usually controlled by the antilock brake system or electronic traction control system.

Well, there you have it. We’ve looked at the AWD systems featured in domestic cars, vans, and crossovers. Join us for upcoming GEARS Magazine articles and webinars featuring diagnostic routines needed to help keep these AWD systems rolling down the road.